Hycor® ThickTech™ RDT Trunnion Wheel Design Improvements

Hycor® ThickTech™ RDT Trunnion Wheel Design Improvements

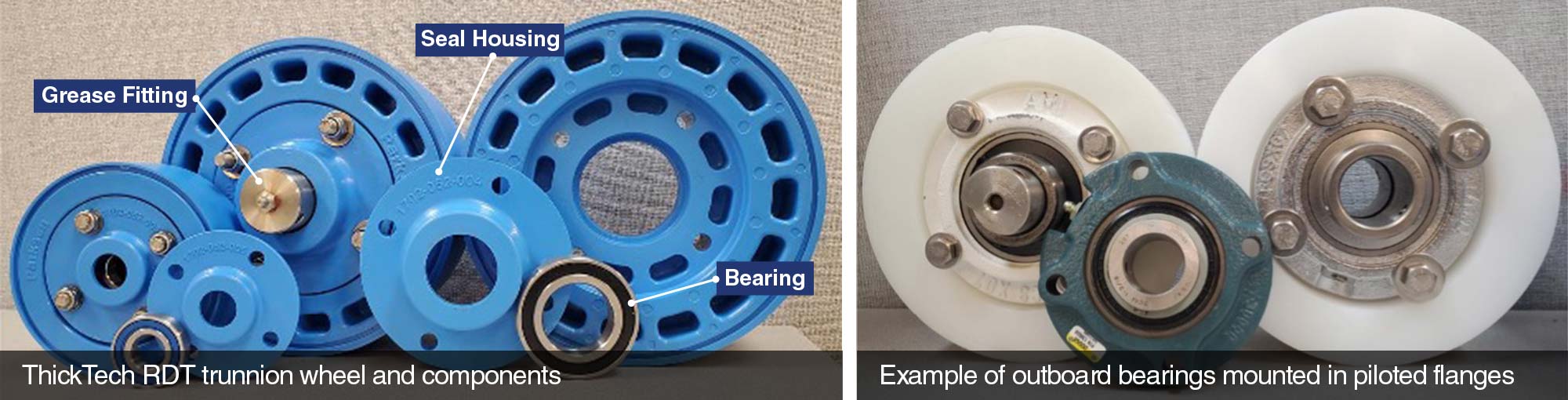

Parkson’s team of engineers have been hard at work developing new trunnion wheels for both existing and new ThickTech Rotary Drum Thickener units. After listening to important feedback from our customers, we have come up with a superior design which is expected to far surpass the life of the existing design. This is accomplished by moving the external bearing into a triple-sealed internal compartment, therefore, providing better protection against elements in the environment such as dirt, water, and corrosive gases. To date, Parkson’s ongoing field test with the new wheel just surpassed 13,000 hours, with lubrication once per week, ensuring the final product meets the rigors of this demanding application.

Multiple seals mounted in the seal housing protect the internally mounted bearings to help the RDT operate without interruption while still achieving unmatched sludge thickening performance. Maintenance remains minimal, as our design team recommends that operators continue to grease bearings once per week to maintain its full life span and keep the unit in operation.

New units have begun to ship with the newly improved trunnion wheels, which are constructed of nylon, maintain an 8” diameter, and feature a 1.5” diameter shaft (for larger units). Existing units can also be retrofitted with the new design wheels with sealed internal bearings. Stock for existing units is currently available. Check with our Aftermarket group for current lead times.

All ThickTech RDT units and the new wheels are designed, fabricated, and assembled in the USA.

For additional information on new RDT units, contact Dave Mitchell. For information on existing units / Aftermarket, contact Ray Coulter.

WaveLink . Quarter 4 / 2021

- Letter from the President

- New! TumbleOx™ TBBR Pilot Testing Available

- Circular Clarifier Retrofit Significantly Improves Flow Rate at Arkansas Plant

- Aqua Guard® Video Captures Unique Design Features, Happy Customers

- Parkson Selected for Multi-Million Dollar Ogg Israel Project Expansion

- Hycor® ThickTech™ RDT Trunnion Wheel Design Improvements

- Parkson Earns 2021 Great Place to Work Certification!

- New Hire Spotlight

- Index